System Level Description of... - Hyjack : Hydrogen Online

System Level Description of Electrolyzers by IRENA

h2ely

Consultant

Published on Feb 03, 2021

This report explores strategies and policies to drive innovation, cut costs for electrolysers and make green hydrogen a least-cost solution wherever needed. With larger production facilities, design standardization and insights from early adopters, the proposed strategies could cut costs by 40% in the short term and up to 80% in the long term, this study finds. The reports contain a clear presentation of the four types of electrolysers: Alkaline and polymer electrolyte membrane (PEM) – already at commercial stage ant Anion exchange membrane (AEM) and solid oxide - now at lab scale, promise a major step forward

Author

IRENA

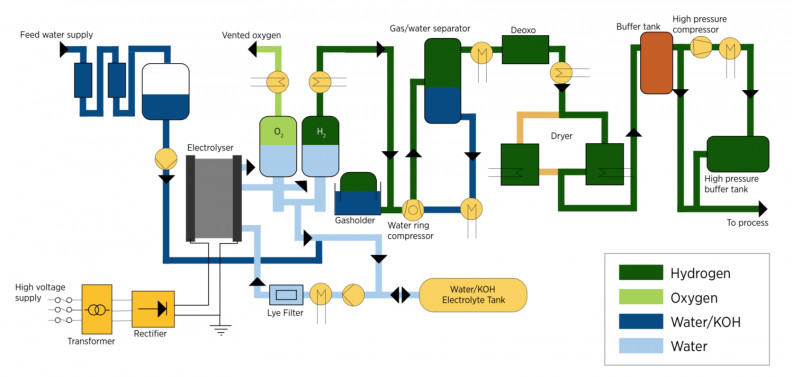

#1

Typical system design and balance of plant for an alkaline electrolyzer

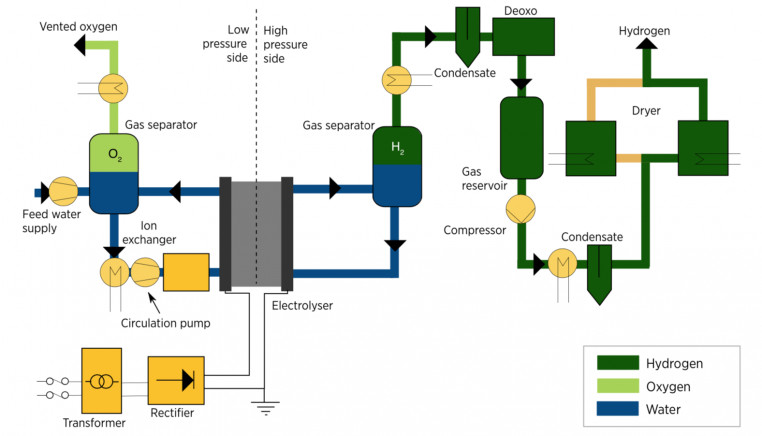

#2

Typical system design and balance of plant for a PEM electrolyzer

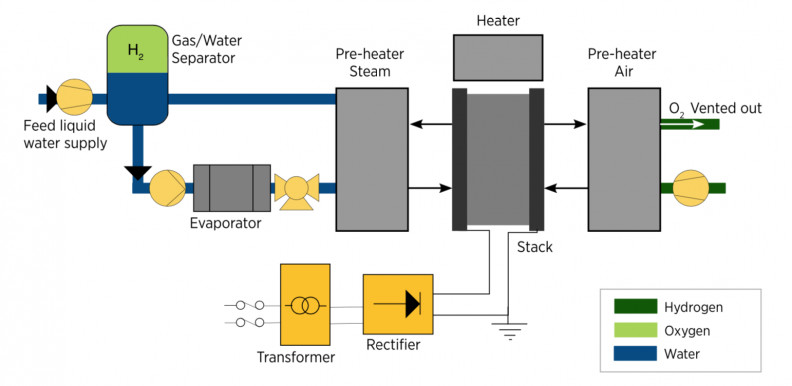

#3

Typical system design and balance of plant for a solid oxide electrolyzer

Link About